1. Cov khoom xaiv:cov khoom siv tus qauv HPB59-1 tooj dag raw khoom, muaj cov khoom siv zoo, tuaj yeem tiv taus kub thiab txias ua haujlwm, siab hardness thiab zoo plasticity, ruaj khov thiab zoo nkauj zoo dua li cov khoom siv stainless hlau.

2. Txiav:Txiav lub tooj liab rau hauv tooj liab ingot nrog tib qhov loj

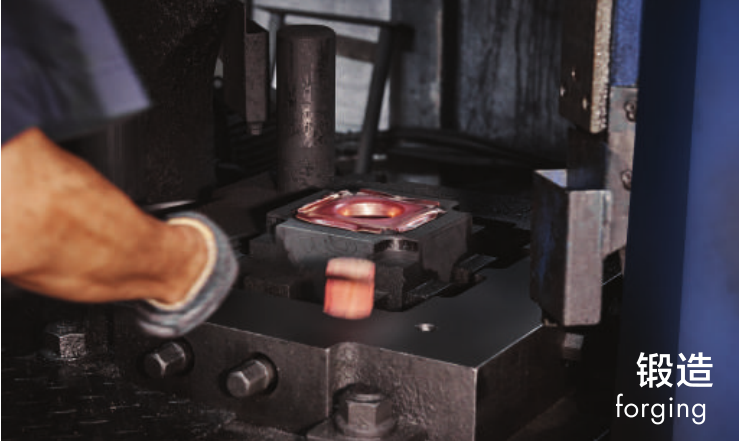

3.Forging:630 tons ntawm CNC hluav taws xob ntsia hlau xovxwm (J58K-630) yog siv rau kub forging ntawm dawb paug, tsim nyob rau hauv ib lub sij hawm, kom lub forging precision yog siab, cov khoom ceev ntawm qhov chaw, lav qhov ceev thiab uniformity ntawm pem teb ntws qauv, lub cev. cov khoom thiab corrosion kuj tau raug txhim kho exponentially, kom tsis txhob deformation, ib lub neej ntawm kev siv.

4. Shape:mechanical kho khoom ntug yog ncaj los tsis.

5. Txiav ntug:tshem tawm cov khoom siv raw khoom

6. Tua blasting:tshem tawm cov oxide nto thiab lwm yam impurities los txhim kho cov tsos zoo, txhim khu kev qaug zog puas ntsoog, tiv thaiv qaug zog tsis ua hauj lwm, yas deformation thiab nkig tawg, txhim kho lub neej qaug zog

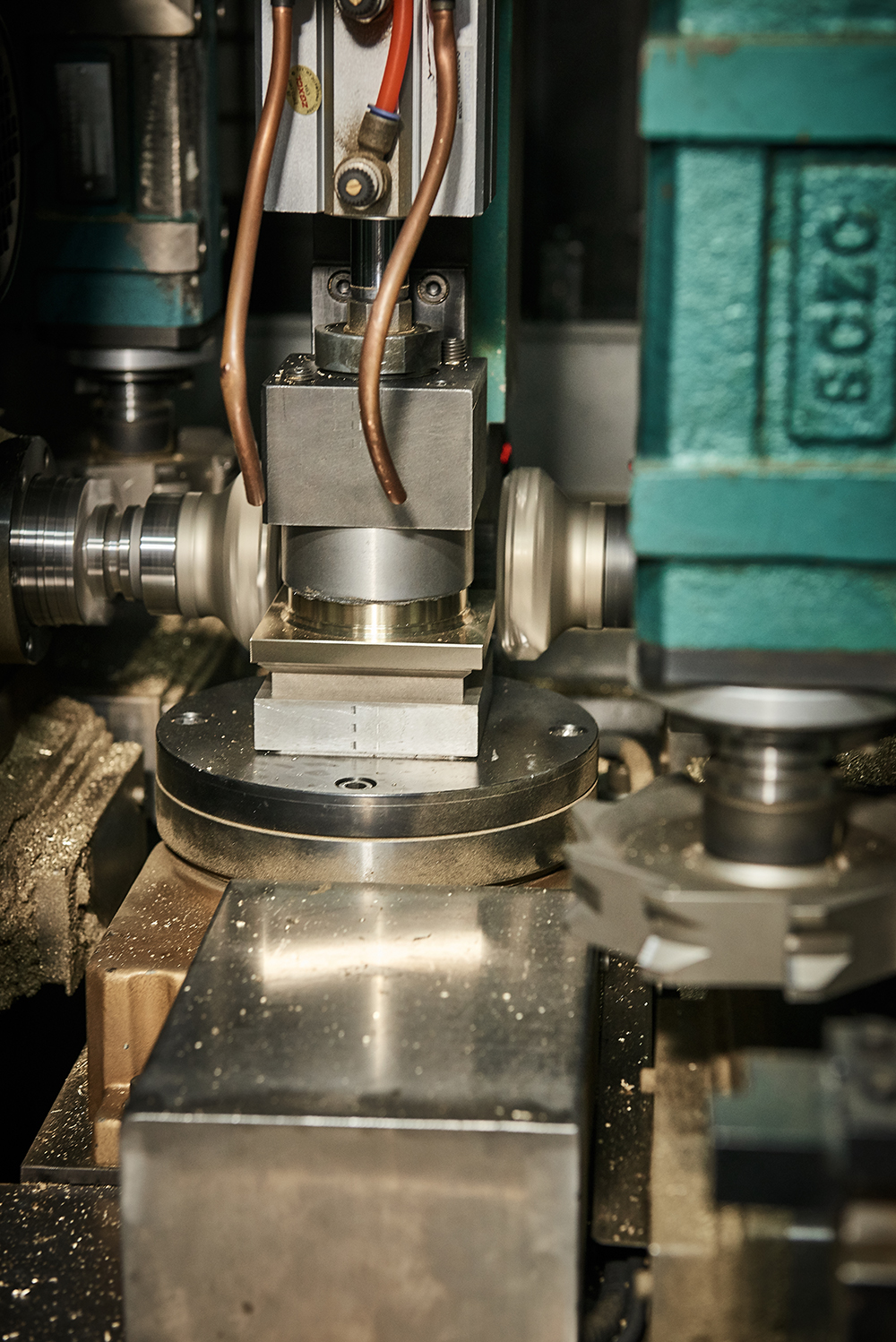

7. Kev tig:tig lub rotating Processed khoom nrog ib tug tig lub cuab tam los xyuas kom meej txoj hauj lwm raug ntawm lub machining nto ntawm cov khoom Processed

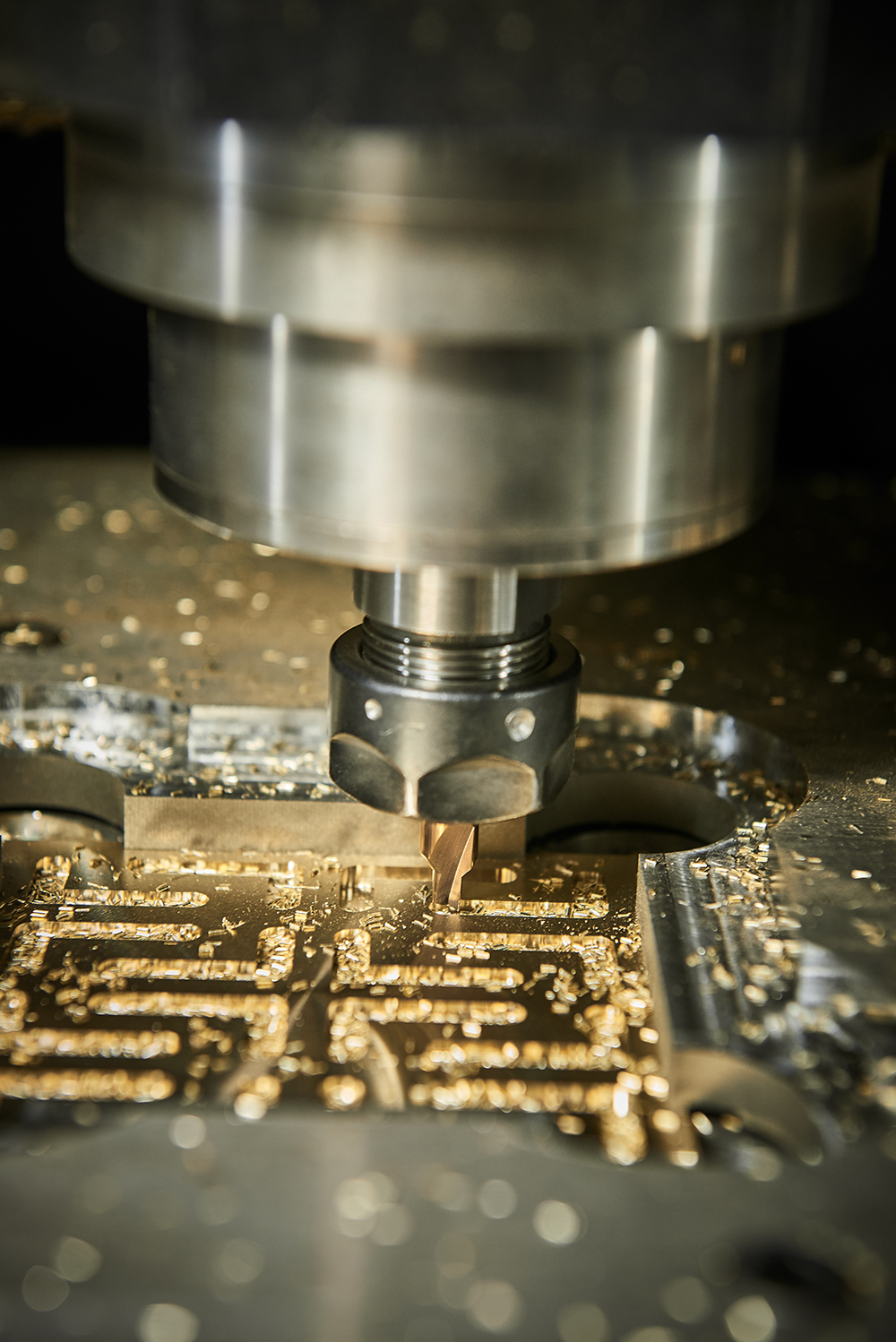

8. Milling ntug:qhov khoob yog tsau los ntawm kev ua milling, thiab kev kub ceev rotating milling cutter mus rau ntawm qhov khoob kom txiav tawm qhov xav tau cov duab thiab nta

9. Sab hauv phab ntsa carving:ua rau lub puab tsaig ntawm hauv pem teb ntws lub cev zoo yam tsis tau pom cov hniav, thiab hauv qab nto yog du thiab meej.

10. qauv carving:puag ncig tsim nyob ib ncig ntawm lub vaj huam sib luag, tsis muaj kev txiav tes, ntug ntawm lub vaj huam sib luag yog refined, thiaj li hais tias cov qauv zoo nkauj muaj ib tug

peb-dimensional kev nkag siab

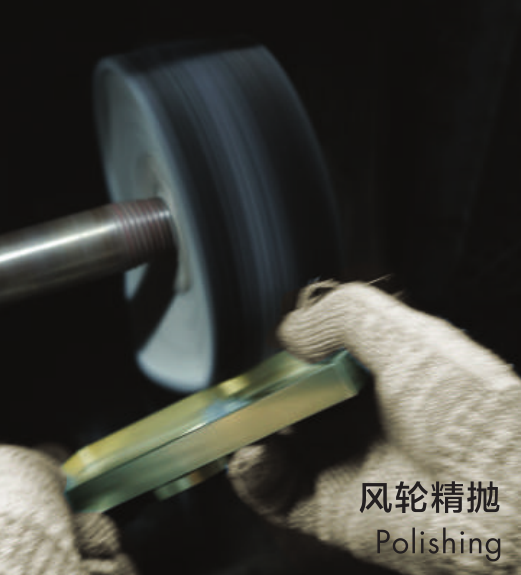

11. polishing:pib polishing ntawm cov khoom nto los ntawm abrasive siv sib tsoo kom txo tau qhov roughness ntawm hauv pem teb ntws

12. precision polishing:los ntawm cov cua log polishing yog kom tau ib tug du nto los yog daim iav luster rau lub hom phiaj, lub high-speed rotating polishing log (circumferential ceev ntawm ntau tshaj 20 m / s) siab rau cov Processed khoom, kom lub abrasive nto ntawm lub Processed cov khoom dov thiab micro txiav, thiaj li kom tau txais cov txheej txheem ci ntsa iab, ua rau cov khoom lag luam zoo heev.

13.Electroplating:cov khoom electroplating qib ntawm 10 μ, nruj raws li daim iav yuav tsum tau ntawm tus txheej txheem ua, 5 txheej ntawm electroplating ua rau cov khoom nto gloss muag.

14.Salt spray test:tag nrho cov khoom raug kuaj 24 teev nruab nrab ntsev tsuag ua ntej tawm hauv lub hoobkas

15. Kev tshuaj xyuas:los ntawm kev tshuaj xyuas cov khoom siv raw, kev kuaj dawb paug, kev tshuaj xyuas tiav, kev tshuaj xyuas polishing, tshuaj xyuas txheej, kev tshuaj xyuas zaum kawg kom paub meej cov khoom zoo.

16. Marking:Laser logo, laser engraving, anti-counterfeiting trademark, qhabnias lav, thov saib rau FENGCAI ncov trademark

17. Ntim:siab zog thiab tuab cov ntaub ntawv tuaj txawv teb chaws, hloov tau thiab muaj zog

Lub tuam txhab xav tau

Kev xaiv chav dej, xaiv lub tsev, xaiv ntau lab tsev neeg tsis muaj dab tsi los ntseeg rov qab, tab sis ua kom zoo dua

Lub luag haujlwm ua haujlwm

Peb lub hom phiaj muab cov neeg siv khoom nrog cov kev daws teeb meem kev noj qab haus huv zoo tshaj plaws thiab dhau los ua lub ntiaj teb-chav nyob hauv cov chaw muab kev pab cuam dej

Post lub sij hawm: Apr-07-2022